What We Do

Our Services Include:

- Cost benefit analysis for capital equipment and projects

- Development of Custom Machines for Manufacturing

-

- Design only

- Design and build with your team

- Turn key supply, build, and commission

- PLC Control Systems & Programming

- Manufacturing System Improvements

- Design for Ease of Manufacture

- Project Management

MDCL staff has over 30 years’ experience in the concept and design of automation machinery and PLC control systems. We can also upgrade older systems and improve your productivity.

MDCL can provide training for your manufacturing staff.

MDCL maintain SolidWorks® CAD design software licenses and can provide your design team with additional manpower during peak times or for specific projects.

Cost Benefit Analysis

Want to replace old equipment or expand into something new but not sure if you will get real value?

Using modern Engineering Management tools and a systems approach we can analyse your options and provide you with the true cost of ownership over the life of the project.

Using modern Engineering Management tools and a systems approach we can analyse your options and provide you with the true cost of ownership over the life of the project.

As an example, we provided a Cost Analysis for new compressed air generating plant. By changing the specification the project recovered capital costs in 27 months.

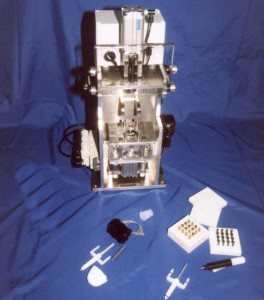

Custom Machinery for Manufacturing

- Design of fully automated assembly machinery and process equipment

- Semi-automatic assembly and manual work stations

- Detailed manufacturing drawings and 3D modelling

- Assembly, commissioning and programming of equipment and PLC controls

- Outsourcing of machining and complete turn-key systems available

- Concepts, estimates and complete project planning for new machines

- Deliver training to staff on new technology

System Improvements

- Plant and equipment upgrades

- Process auditing

- Mechatronic conversion of old equipment to improve reliability and output

- Concept and feasibility studies on the practicality of automation applications

Design for Manufacture

- Consult on manufacturability of new product and guide manufacture and assembly

- Create manufacturing drawings, BOM’s

- Develop your prototype to production readiness

Project Management

- Using modern Systems Engineering Methods we can create and supervise a project plan with a higher than average rate of success

- Assemble and manage outside suppliers and contractors to work on your industrial projects

- Cost analysis, specification and installation of new plant

- Undertake local and overseas research for selection of manufacturing machinery